Essential Elements of Cell and Gene Therapy: Packaging and Delivery

May 24,2022

Category: Foundational Processes, Packaging Development, Regulatory Compliance

With gene and cell therapies changing the face of healthcare, it’s no wonder there are more and more gene/cell therapy clinical trials in progress worldwide every year. The nature of these products and their supply chain make maintaining a harmonious supply chain critical, but that isn’t necessarily easy to achieve. To ensure the safe delivery of products to patients, there are four main areas to consider as part of the packaging and distribution process:

Packaging systems, including primary, secondary and tertiary packaging, must not only meet Current Good Manufacturing Practice (CGMP) regulatory requirements, but also maintain product stability and closure integrity. The packages must be easily accessible, and regulations require that they display chain of identity information for clinicians, end users and manufacturers. There are a few other key considerations for packaging engineers as they design solutions for cell and gene therapy products.

Regulatory bodies such as the Food and Drug Administration (FDA), United Nations and the U.S. Department of Transportation outline the measures shippers need to follow to avoid penalties. Since hazardous classification requirements affect the design and packaging process of gene therapy products or intermediates, developing comprehensive packaging and labeling requirements documents is imperative. Inadequately preparing and developing your packaging design could endanger qualification testing or the actual clinical and commercial launches.

Noncompliance with regulations and insufficient qualification could result in severe penalties. Hazardous material leakages can lead to an FDA audit, which if failed, can lead to fines and other penalties. For that reason, sufficient training for personnel within the supply chain is vital to compliance. Appropriate paperwork should also accompany shipments. Improper hazardous material shipments can lead to criminal and civil penalties and fines ranging from $250 to $500,000 per violation. Additionally, certification for bodies such as the International Air Transport Association (IATA) require recertification every two years.

Cold Chain Packaging

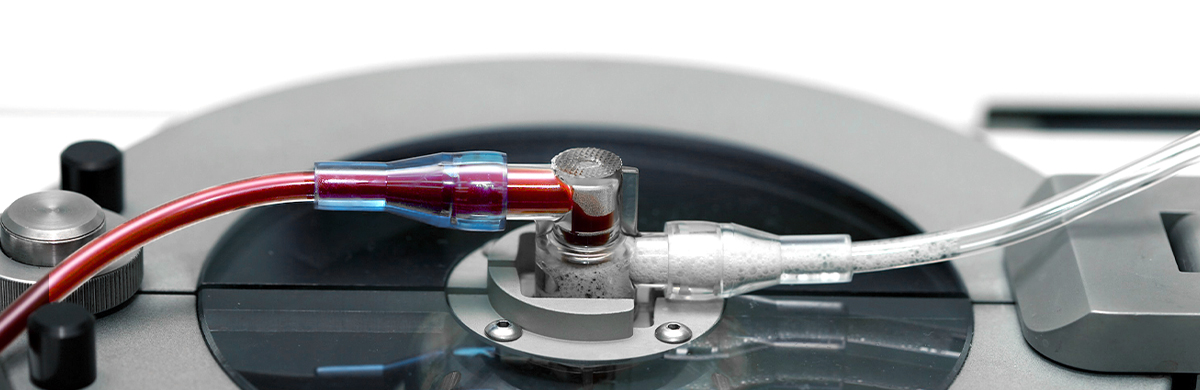

Every step of the supply chain requires an understanding of the unique packaging and temperature parameters for compliance with patient safety regulations. Comprehensive data is necessary to establish temperature ranges and possible allowable temperature excursions for each individual product, such as apheresis kits and viral vectors. This data needs to be supported by rigorous qualification under simulated conditions and withstand the exerted physical and thermal stresses during handling and shipping. For gene therapy products that often must be kept at cryogenic temperatures to maintain their potency, a two-shipper system can usually accommodate this requirement by way of a dry ice shipper and dry nitrogen vapor shipper, but must be thoroughly evaluated to determine acceptance.

Thermal shipping systems should include built-in temperature monitors in sensitive locations and sensors that measure temperature and information on location, vibration, shock and orientation. Shippers and couriers should maintain records and end-to-end logistical support to ensure performance and consistency. These are all requirements of gene and cell therapy cold chain solutions.

Traceability - Chain of Identity

Maintaining chain of identity and custody throughout the supply chain is vital since each autologous cell therapy product is personalized for patients. Chain of identity allows for the tracking of individual therapy products for patients, whereas chain of custody refers to tracking throughout the supply chain. The chain of identity creation process should be documented and plainly visible in the batch record. It also should include apheresis collection data until the product reaches the patient. Traceability solutions have made the shipment and tracking of cell and gene therapy products easier to manage, but since use cases are still fairly new, they require careful configuration, evaluation and implementation.

How We Can Help

Creating a gene therapy packaging program is a complex process. It’s more than regulations; successful packaging has to overcome several hurdles in an ever-changing, often chaotic environment. Adept Packaging can help. Contact us today to learn more about how to better support your gene therapy packaging program to reduce risk and allow your team to continue saving lives.

- Packaging engineering

- The qualification of hazardous materials

- Cold chain packaging

- Traceability - chain of identity

Packaging systems, including primary, secondary and tertiary packaging, must not only meet Current Good Manufacturing Practice (CGMP) regulatory requirements, but also maintain product stability and closure integrity. The packages must be easily accessible, and regulations require that they display chain of identity information for clinicians, end users and manufacturers. There are a few other key considerations for packaging engineers as they design solutions for cell and gene therapy products.

- The entire packaging system, from operational and performance qualification through shipment during commercialization, must be hold up against thermal and mechanical stress.

- Regulations require separation between primary containers, leak-proofing and internal pressurization tests.

- Primary and secondary packages should be designed to maintain their state and durability when exposed to cryogenic temperatures.

- Secondary and tertiary labels must be qualified against abrasion and adhesion through tests that replicate actual storage and shipping conditions and be tamper evident and contain hazard-related information.

- Packaging should prevent contamination of gasses such as CO2 and liquid or vapor nitrogen.

Regulatory bodies such as the Food and Drug Administration (FDA), United Nations and the U.S. Department of Transportation outline the measures shippers need to follow to avoid penalties. Since hazardous classification requirements affect the design and packaging process of gene therapy products or intermediates, developing comprehensive packaging and labeling requirements documents is imperative. Inadequately preparing and developing your packaging design could endanger qualification testing or the actual clinical and commercial launches.

Noncompliance with regulations and insufficient qualification could result in severe penalties. Hazardous material leakages can lead to an FDA audit, which if failed, can lead to fines and other penalties. For that reason, sufficient training for personnel within the supply chain is vital to compliance. Appropriate paperwork should also accompany shipments. Improper hazardous material shipments can lead to criminal and civil penalties and fines ranging from $250 to $500,000 per violation. Additionally, certification for bodies such as the International Air Transport Association (IATA) require recertification every two years.

Cold Chain Packaging

Every step of the supply chain requires an understanding of the unique packaging and temperature parameters for compliance with patient safety regulations. Comprehensive data is necessary to establish temperature ranges and possible allowable temperature excursions for each individual product, such as apheresis kits and viral vectors. This data needs to be supported by rigorous qualification under simulated conditions and withstand the exerted physical and thermal stresses during handling and shipping. For gene therapy products that often must be kept at cryogenic temperatures to maintain their potency, a two-shipper system can usually accommodate this requirement by way of a dry ice shipper and dry nitrogen vapor shipper, but must be thoroughly evaluated to determine acceptance.

Thermal shipping systems should include built-in temperature monitors in sensitive locations and sensors that measure temperature and information on location, vibration, shock and orientation. Shippers and couriers should maintain records and end-to-end logistical support to ensure performance and consistency. These are all requirements of gene and cell therapy cold chain solutions.

Traceability - Chain of Identity

Maintaining chain of identity and custody throughout the supply chain is vital since each autologous cell therapy product is personalized for patients. Chain of identity allows for the tracking of individual therapy products for patients, whereas chain of custody refers to tracking throughout the supply chain. The chain of identity creation process should be documented and plainly visible in the batch record. It also should include apheresis collection data until the product reaches the patient. Traceability solutions have made the shipment and tracking of cell and gene therapy products easier to manage, but since use cases are still fairly new, they require careful configuration, evaluation and implementation.

How We Can Help

Creating a gene therapy packaging program is a complex process. It’s more than regulations; successful packaging has to overcome several hurdles in an ever-changing, often chaotic environment. Adept Packaging can help. Contact us today to learn more about how to better support your gene therapy packaging program to reduce risk and allow your team to continue saving lives.