Pallet Pattern Optimization

.jpg)

June 16,2022

Category: Packaging Development

For brands seeking opportunities to reduce costs for packaging and shipping, optimizing their distribution is an easily overlooked, but often powerful source of savings. With fuel and material costs at all-time highs, many companies are looking for ways to offset those expenses. Transportation of finished goods is a significant contributor to cost of goods sold, and careful examination of pallet arrangements can reveal easy opportunities for major reductions in transportation costs.

What Does Pallet Optimization Look Like?

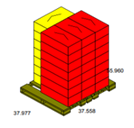

Optimized palletization can reduce transportation costs by up to 50%, but many packaging teams may not be aware of these opportunities. To optimize pallet configurations, brands must explore alternative packaging materials and packaging designs that not only protect the product, but also maximize the amount of product that will fit on a pallet. When done right, this process allows brands to save on transportation and fuel costs that improve sustainability by reducing the number of trucks required to transport product, all without directly impacting consumers.

Perhaps most importantly, the changes required to enable more efficient pallet patterns are invisible to the consumer, meaning packaging and shipping departments can deliver significant cost savings without sacrificing brand perception.

Options for Brands

The above example also illustrates the use of wooden pallets, which helps in the structure of double stacked pallets. The wooden pallet, however, can be replaced by a slip sheet–in this case, increasing the viable cases per stack by nearly 15%. Slip sheets are typically made of lightweight fiberboard, making them not only cost-effective, but sustainable since they are 100% recyclable. Removing pallets from your shipments and replacing them with slip sheets will give you the opportunity to eliminate unnecessary waste and spending. Based on average prices, slip sheets are 20% of the price of wooden pallets and occupy significantly less space, creating additional opportunities for savings.

Efficient palletization helps improve the cost structure of your products with virtually no impact to your customer. Pallet pattern optimization reduces costs related transportation, fuel, and labor while improving sustainability of your shipping and distribution operations.

If you think your brand could benefit from pallet pattern optimization and you’re interested in discussing options for your brand, get in touch with our team.

What Does Pallet Optimization Look Like?

Optimized palletization can reduce transportation costs by up to 50%, but many packaging teams may not be aware of these opportunities. To optimize pallet configurations, brands must explore alternative packaging materials and packaging designs that not only protect the product, but also maximize the amount of product that will fit on a pallet. When done right, this process allows brands to save on transportation and fuel costs that improve sustainability by reducing the number of trucks required to transport product, all without directly impacting consumers.

Perhaps most importantly, the changes required to enable more efficient pallet patterns are invisible to the consumer, meaning packaging and shipping departments can deliver significant cost savings without sacrificing brand perception.

Options for Brands

The above example also illustrates the use of wooden pallets, which helps in the structure of double stacked pallets. The wooden pallet, however, can be replaced by a slip sheet–in this case, increasing the viable cases per stack by nearly 15%. Slip sheets are typically made of lightweight fiberboard, making them not only cost-effective, but sustainable since they are 100% recyclable. Removing pallets from your shipments and replacing them with slip sheets will give you the opportunity to eliminate unnecessary waste and spending. Based on average prices, slip sheets are 20% of the price of wooden pallets and occupy significantly less space, creating additional opportunities for savings.

Efficient palletization helps improve the cost structure of your products with virtually no impact to your customer. Pallet pattern optimization reduces costs related transportation, fuel, and labor while improving sustainability of your shipping and distribution operations.

If you think your brand could benefit from pallet pattern optimization and you’re interested in discussing options for your brand, get in touch with our team.