Smart Packaging Design for Efficiency

March 22,2023

Category: Cost Savings, Packaging Development, Quality Optimization, Sustainability

Design plays many important roles in packaging. Its impact on consumer experience and its ability to communicate key product information may be the first that came to mind, but well-thought-out, efficient packaging design can also help brands save on costs.

For brands with multiple products of similar size and protection requirements, leveraging design to create common packaging components can be a key driver of efficiency.

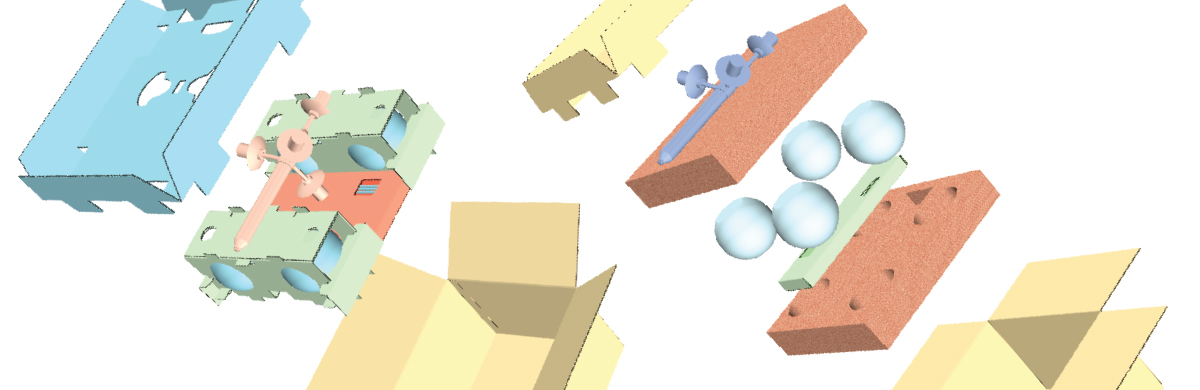

The best approach to designing packaging components that work across a range of products is to think from the outside in. The outer components of a package are the strongest candidates for standardization across multiple products because they usually have the least direct contact with the individual product inside. Inner components such as trays usually have more direct contact and often need to be shaped to secure the product snugly.

When designing shared packaging components, it’s helpful to design for the largest and smallest products across the range. Designing components whose size and shape accommodate the largest product while minimizing wasted space around the smallest ensures the packaging is versatile enough for its intended purpose.

Inner components such as trays or folded corrugate can be customized to accommodate the individual variations in size and shape between each product while working cohesively with the shared packaging components.

Identifying and implementing share packaging components can improve packaging process efficiency and bring down material costs.

By utilizing common packaging elements across a range of products, packaging departments can reduce the amount of space needed to store material inventory. This approach also enables a brand to optimize utilization of assets like machinery and space throughout the packaging facility.

Maximizing the shared packaging components used across multiple products also allows a packaging department to purchase a smaller number of materials in higher quantities. This increases spending power and provides greater leverage when negotiating with suppliers, creating opportunities to reduce per-unit costs.

If your brand is using overly specialized packaging components across products that may benefit from some standardization, outside support from an experienced packaging designer can provide a fresh perspective that will help you identify opportunities. Get in touch with Adept Group to discuss how our experts can help you develop more efficient packaging and tackle a variety of other cost-saving challenges.

For brands with multiple products of similar size and protection requirements, leveraging design to create common packaging components can be a key driver of efficiency.

Process Considerations

The best approach to designing packaging components that work across a range of products is to think from the outside in. The outer components of a package are the strongest candidates for standardization across multiple products because they usually have the least direct contact with the individual product inside. Inner components such as trays usually have more direct contact and often need to be shaped to secure the product snugly.When designing shared packaging components, it’s helpful to design for the largest and smallest products across the range. Designing components whose size and shape accommodate the largest product while minimizing wasted space around the smallest ensures the packaging is versatile enough for its intended purpose.

Inner components such as trays or folded corrugate can be customized to accommodate the individual variations in size and shape between each product while working cohesively with the shared packaging components.

The Benefits

Identifying and implementing share packaging components can improve packaging process efficiency and bring down material costs.By utilizing common packaging elements across a range of products, packaging departments can reduce the amount of space needed to store material inventory. This approach also enables a brand to optimize utilization of assets like machinery and space throughout the packaging facility.

Maximizing the shared packaging components used across multiple products also allows a packaging department to purchase a smaller number of materials in higher quantities. This increases spending power and provides greater leverage when negotiating with suppliers, creating opportunities to reduce per-unit costs.

If your brand is using overly specialized packaging components across products that may benefit from some standardization, outside support from an experienced packaging designer can provide a fresh perspective that will help you identify opportunities. Get in touch with Adept Group to discuss how our experts can help you develop more efficient packaging and tackle a variety of other cost-saving challenges.