Cost-Effective and Sustainable POP Display Optimization

Client Overview

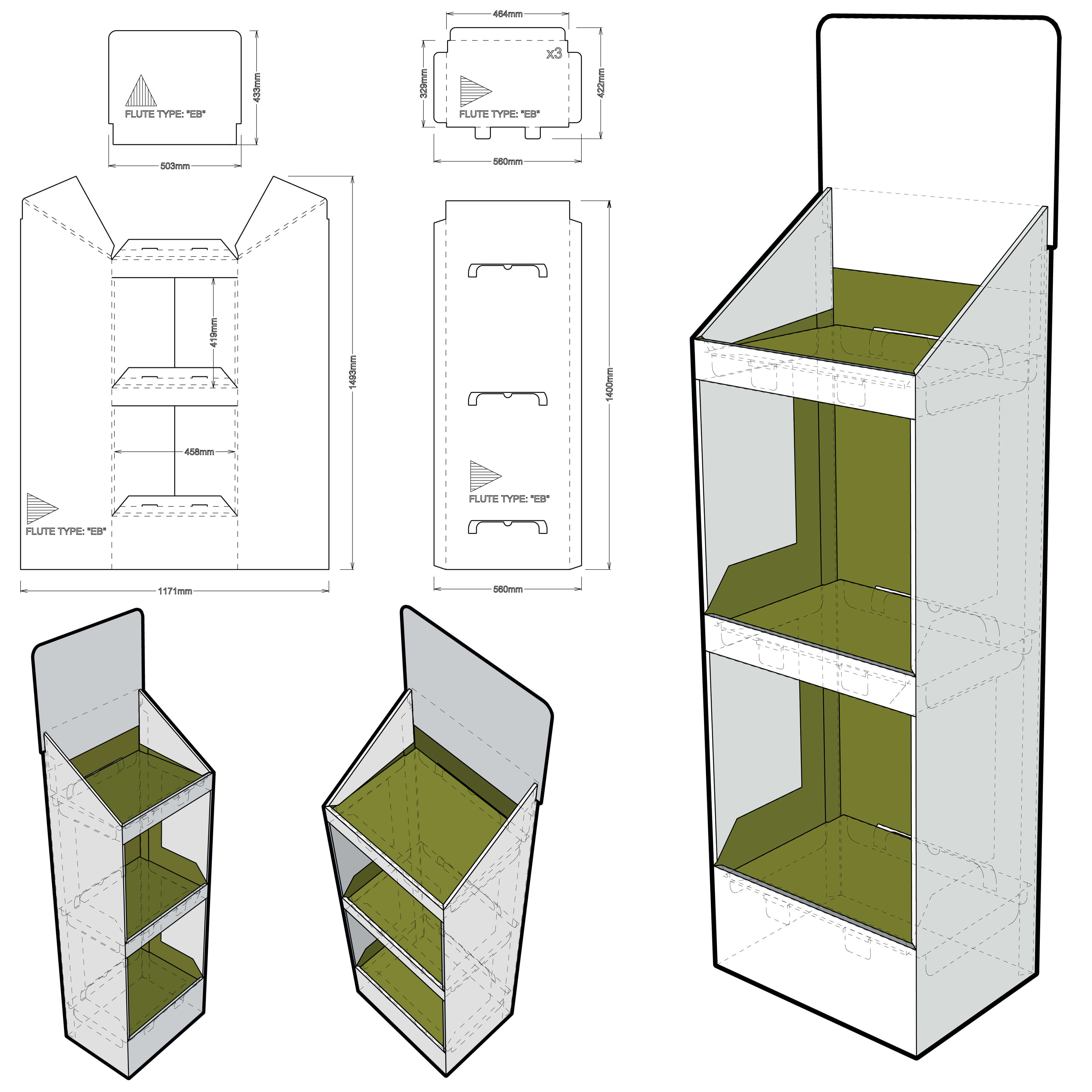

A nationally recognized food manufacturer turned to Adept to redesign its point-of-purchase (POP) display trays. The company was facing increased material costs and inefficiencies due to outdated display structures that weren’t optimized for current packaging formats. With sustainability and shelf appeal both top priorities, the client needed a structural redesign that would reduce costs, improve visibility, and meet retail requirements.

Adept delivered a cost-effective, sustainable, and visually optimized POP display solution. The redesigned tray not only reduced cost and waste but also improved in-store presentation, helping the brand better connect with customers and meet its sustainability goals.

The Challenge

The client’s existing POP display trays were overbuilt and used excessive material, contributing to higher production costs and unnecessary waste. At the same time, their marketing team wanted improved shelf presence for retail environments without compromising structural integrity.

Create a new POP display tray with reduced material consumption and production cost

Improve visibility and branding space for in-store display

Maintain necessary strength and stability for product protection and retail handling

Eliminate outdated formats that didn’t align with evolving product shapes and sizes

Develop a repeatable structural solution applicable across multiple SKUs

Our Approach

Adept conducted a structural and cost analysis of the client’s current display system. We evaluated the primary pack configurations, tested new tray structures, and collaborated with marketing and operations teams to ensure the new design met functional and visual needs.

Identified redundant flaps and overbuilt structural elements for material reduction

Designed a right-sized tray format with improved branding panel and retail presence

Validated the new structure for strength and transport performance

Delivered production-ready samples and supplier-ready specifications

The Impact

Adept's end-to-end optimization delivered more than just higher numbers:

30% reduction in material consumption through streamlined structural redesign

$16,000 in projected annual savings from tray material and process improvements

Enhanced retail visibility with optimized tray layout and print panel placement

Improved supply chain efficiency through simpler and faster assembly

This isn't just a fix. It’s a transformation.

Let’s Talk Efficiency Gains

Want to reduce production costs, increase throughput, or optimize your packaging line? Let’s connect.