Designing Packaging to Protect the Product

Packaging that fails to adequately protect the product during shipping is likely to incur damage that drives unplanned costs. There are many potential hazards a package will face as it makes its way from the manufacturer to the customer, so it’s important that the primary focus when designing packaging is protecting the product. While this may be true, there are also risks of designing a package that provides more protection than needed, which also drives unnecessary costs and creates unnecessary waste. There are a handful of important considerations that can serve as a guide to optimizing the packaging design to protect the product and ensure it reaches the customer free of damage.

Consider the Distribution Environment

As supply chains gain more complexity, more touchpoints often result in more opportunities for package damage. As a result, designing with the entire distribution environment in mind minimizes the potential for costly problems as the product and its packaging move through the system. Understanding the needs of the product, where it ships from and its ultimate destination provides much the information needed to design packaging that provides adequate protection. Knowing whether the packaging will be shipped domestically or travel overseas will help inform how the packaging needs to perform.

A package will likely face a variety of shipping and storage conditions before it reaches the consumer. It may depart the packaging line as part of a unitized load, spend time in a warehouse, get shrink-wrapped with other packages of varying size and shape on a pallet, and face unpredictable conditions during last-mile delivery.

It is also helpful to plan for the unique conditions and hazards the product and its packaging will encounter throughout the distribution environment. During its journey, a package may spend time in a warehouse where temperature and humidity are not controlled, meaning it must endure a range of ambient conditions. Products intended for retail sales and e-commerce distribution will pass through a different number of touchpoints, with e-commerce often involving up to three times as many. Each touchpoint is another opportunity for the package to face conditions that may lead to damage. Designing with the distribution environment in mind also helps reduce time and expenses to successfully qualify the package design.

Design for Secondary Packaging & Stacking

Careful consideration of the product and its distribution environment provides the background necessary to choose the right packaging materials and design. While an understanding of the product and the conditions its packaging will face are a good start, but packaging design also needs to account for the time the package will spend stacked on a pallet as a unitized load. The package design needs to support stacking a full pallet load without compromising the integrity of the packages at the bottom of the stack. The design also needs to be efficient enough to optimize the number of packages that fit on each pallet and eliminate wasted space within each package.

An efficient design includes a stacking pattern that accounts for transport overhang and underhang to protect against damage. The stacking pattern should feature the corrugation direction that provides the most stacking strength. Column stacking is ideal, as it provides point-to-point contact of cartons and eliminates shifting on the pallet.

Rightsizing to Reduce Cost and Improve Sustainability

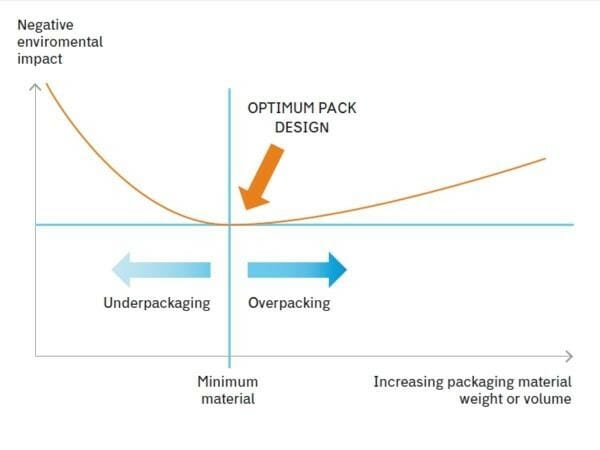

Overpackaging can ensure the product arrives without damage, but it adds to the cost of materials and shipping. It also increases the amount of waste from the packaging, thereby reducing the sustainability of the package. Underpackaging can save on material and transportation costs, but puts the product at risk of shipping damage, leading to costly warranty claims, returns and repacking. The best design is the one that treads the fine line between these extremes. It optimizes packaging materials with just the right amount to make sure the product arrives at its final destination safely.

To create a design that is sized to fit the product and meets the sweet spot between over and under packaging, many factors must be considered. Knowing your distribution environment, unique product needs and accounting for secondary packaging requirements is a start. In addition, understanding the material properties of your package and how the integrity of the package might break down when exposed to temperature fluctuations, shock, stacking, and vibration will help you make decisions about choosing materials, components and a design that suits the unique needs of your product.

Lean on the Experts

Designing packaging the optimizes protection and minimizes costs can be challenging, but leaning on trusted experts can help your brand get it right. Adept Group has experts in packaging for all industries, and we have the experience to identify the design that works best for your product. If you’re getting ready to roll out a new product, experiencing damage you’d like to remediate or redesigning packaging for an existing product, reach out. We’re ready to help.