Implementing a Packaging Innovation Cycle

Implementing a packaging innovation cycle provides a consistent pipeline of news ideas that help brands adapt to stay ahead of the curve as consumer preferences, legislation and packaging technology evolves. Packaging innovation can take many forms. It can be easy to shoehorn the concept of innovation into tangible outputs like new inventions, but innovation can also take the form of improvements to existing materials and processes. Examples of packaging innovation span a broad range, including improvements to process efficiency, extending shelf life for perishable goods, design choices that provide better brand awareness in a competitive marketplace, optimizations that drive cost savings, improvements to packaging sustainability and many more.

Building a Cross-Functional Team

Successfully creating a pipeline of innovation requires input from cross-functional teams throughout the company, and keeping other departments involved throughout the cycle helps to drive buy-in from the entire organization. The most obvious group that plays an important role in this cycle is packaging/development. The packaging department’s relationship with the procurement team is an avenue into the best insights on suppliers and new materials. They have relationships that allow them to challenge supplier to innovate with materials. Informed packaging pros can also provide insight into the latest trends in packaging in both the company’s industry and in other industries.

Marketing plays a critical role by providing insight into market trends and consumer preferences. They can act as the voice of the consumer throughout the innovation cycle.

Operations and production staff have relationships with original equipment manufacturers (OEMs) that can provide insight into how innovation and change impact production costs and potential downtime. They also can provide valuable input in terms of advances in packaging technology and automation that may improve cost and time efficiency.

Sales also plays a critical role through their relationships with retailers and other distribution partners. They’re on the front lines in terms of feedback from these key partners and can highlight issues with products and packaging. They should focus on how the packaging will work with shelf space at retail or in warehouses and distribution centers. They should also know which products are in danger of being de-listed, as these are the products whose packaging is most in need of innovation.

A Stage Gate Approach

With the key contributors in place, it’s important to establish a process for keeping the packaging innovation cycle organized and on track. Because of the variety of departments and business functions whose input impacts packaging innovation, a stage gate approach is the best way to organize the process and make clear who is responsible for each step.

The stage gate approach organizes the development process and creates accountability at the end of each stage. This accountability ensures that the process does not move forward without agreement from the relevant cross-functional teams. It also provides a clear understanding of the activities and deliverables involved in each stage.

For the purposes of packaging innovation, the process works best when broken down into four stages. This approach starts with a scoping stage where the project’s goals and available resources are established. It is also helpful to establish a project charter during this stage, including clear, measurable goals agreed upon by all stakeholders.

The second stage is the design phase, which begins with building a business case that evaluates the project’s potential benefits, costs, and risks of action or inaction. If the business case demonstrates that the project will provide a benefit to the business, the cross-functional team can collaborate to build out a development plan and begin the early phases of design work on the packaging solution.

The third stage focuses on development, including iterating on designs concepts until the team reaches a consensus on which design or designs to advance to the testing phase. The chosen design(s) then go through operation and production testing to ensure they meet the product’s packaging needs as defined by the project charter. When the team reaches a consensus on the new package design that best accomplishes the project’s goals, the packaging team can then decide on an approach to scale up production.

The final stage includes all of the cross-functional team’s launch efforts. Packaging and operations get the final design into full scale production while sales introduces the new packaging to retail and distribution partners and marketing initiates their efforts to communicate the brand’s message to consumers.

Creating an Innovation Cycle

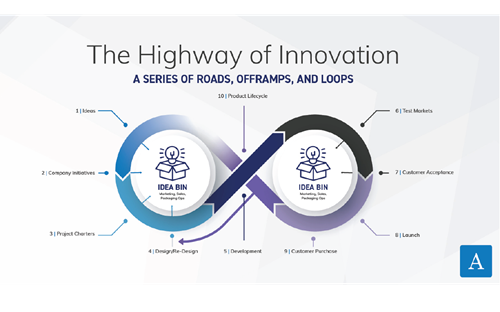

While the stage gate approach is a key to maintaining organization within the packaging innovation process, it is also important to understand that a steady pipeline of innovative ideas requires an ongoing cycle with no true end. An important note about the cyclical nature of an innovation cycle is that no idea is ever truly discarded. While some ideas may not be feasible right now, the process should include an “idea bin” for concepts that don’t make the cut as cross-functional team moves through the stage gate process. An idea or project that gets filtered out at any stage of the process may make more sense later or serve as inspiration for a breakthrough idea the propels packaging in an innovative direction.

Each iteration of this ongoing cycle starts with a defined problem the organization needs to solve or a novel idea that can drive improvements the organization didn’t know it needs. Initiating the cycle is most challenging part, and the concept of the “idea bin” serves as fuel that helps to keep the cycle progressing over a long period of time. This initiation generally kicks off with ideation sessions with the cross functional team working towards of goal finding out what the company needs from its packaging. The broad concept of a packaging need can grow into a set of defined goals around which the entire team aligns.

Those goals inform and guide the creation of designs or concepts that help satisfy the company’s packaging need before gathering feedback from marketing and sales that reflects how they expect both retail partners and consumers to receive the new idea. The packaging team can apply that feedback to further refine these designs and concepts before creating a prototype or test run that can be evaluated under real-world conditions before deciding on a final solution.

Any ideas filtered out throughout this cycle go back into the idea bin to serve as fuel the next time the cross-functional team tries to assess the company’s packaging needs and initiate the next pass through the innovation cycle.

While incorporating an innovation cycle into a packaging team’s creative process may look intimidating, it gets easier over time. If you’re starting to feel like your packaging could use a revamp and don’t know how to initiate a continuous innovation cycle to stay ahead of the curve, the Adept team is ready to help you get started. Get in touch to learn more about how our team of experts can help you tap into the innovative and creative capabilities of your organization.